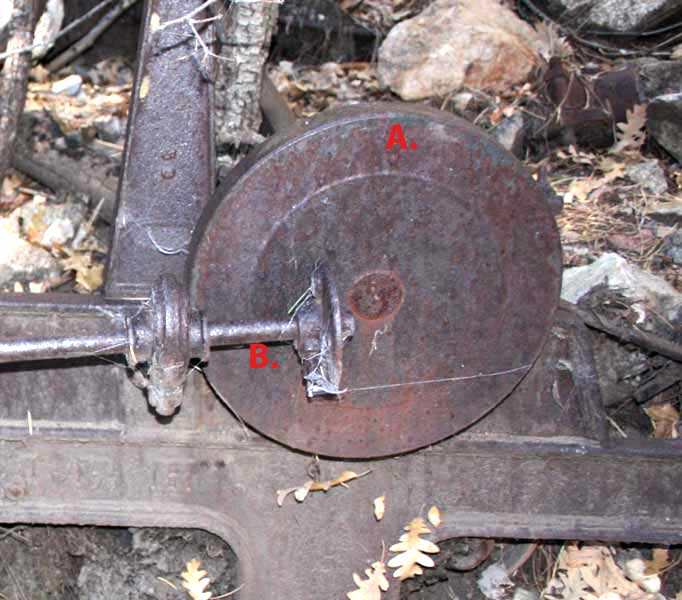

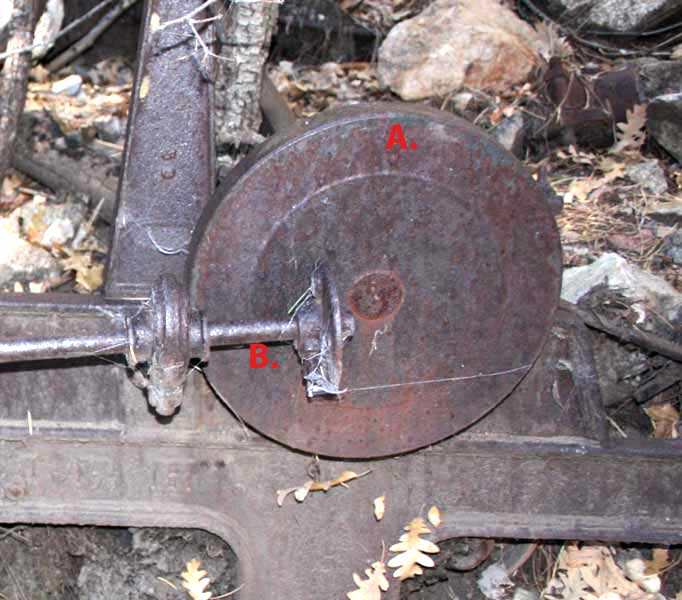

The large wheel(A) was

called a friction disc. Its rotational speed was controlled by

the power source. The smaller wheel(B) at the end of the rod was

called a friction pulley.

It rubbed on the friction disc and could be moved from or toward

the center of the disc. As it was

moved outward its speed would increase or if moved inward the

speed would decrease. The ideal setting was about 230 rpm.